Super Truckin’

Heavy duty trucks transport about 70% of our goods and materials around the country and account for 10% of all miles driven on US highways. The bad news is, most big rigs travel about 6 miles per gallon of fuel, so the need to improve truck efficiency is more crucial than ever. Well, the US Department of Energy has come up with a way to find those answers.

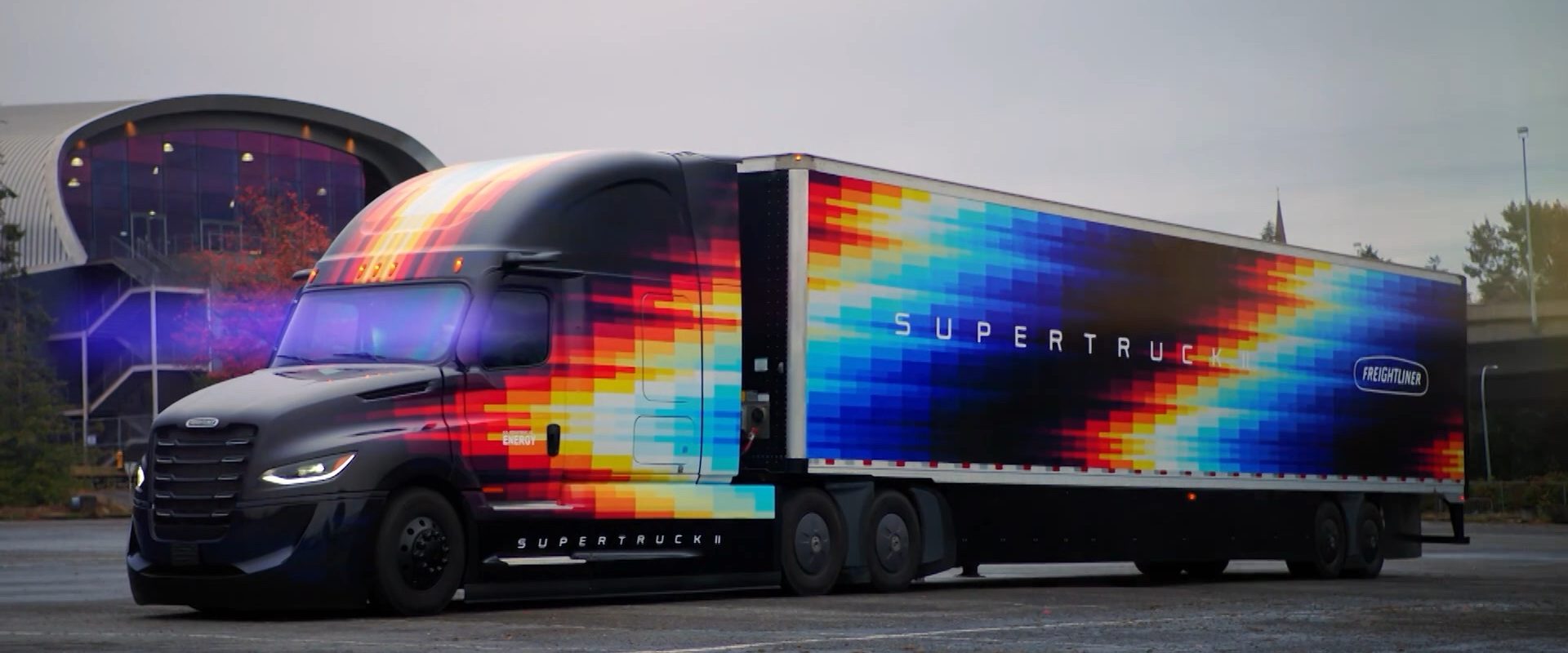

Kicking off in 2010 and now entering its third iteration, SuperTruck is a Department of Energy-funded research program aimed at helping truck makers achieve ambitious gains in freight efficiency, or ton-miles per gallon, for the next generation of big rigs.

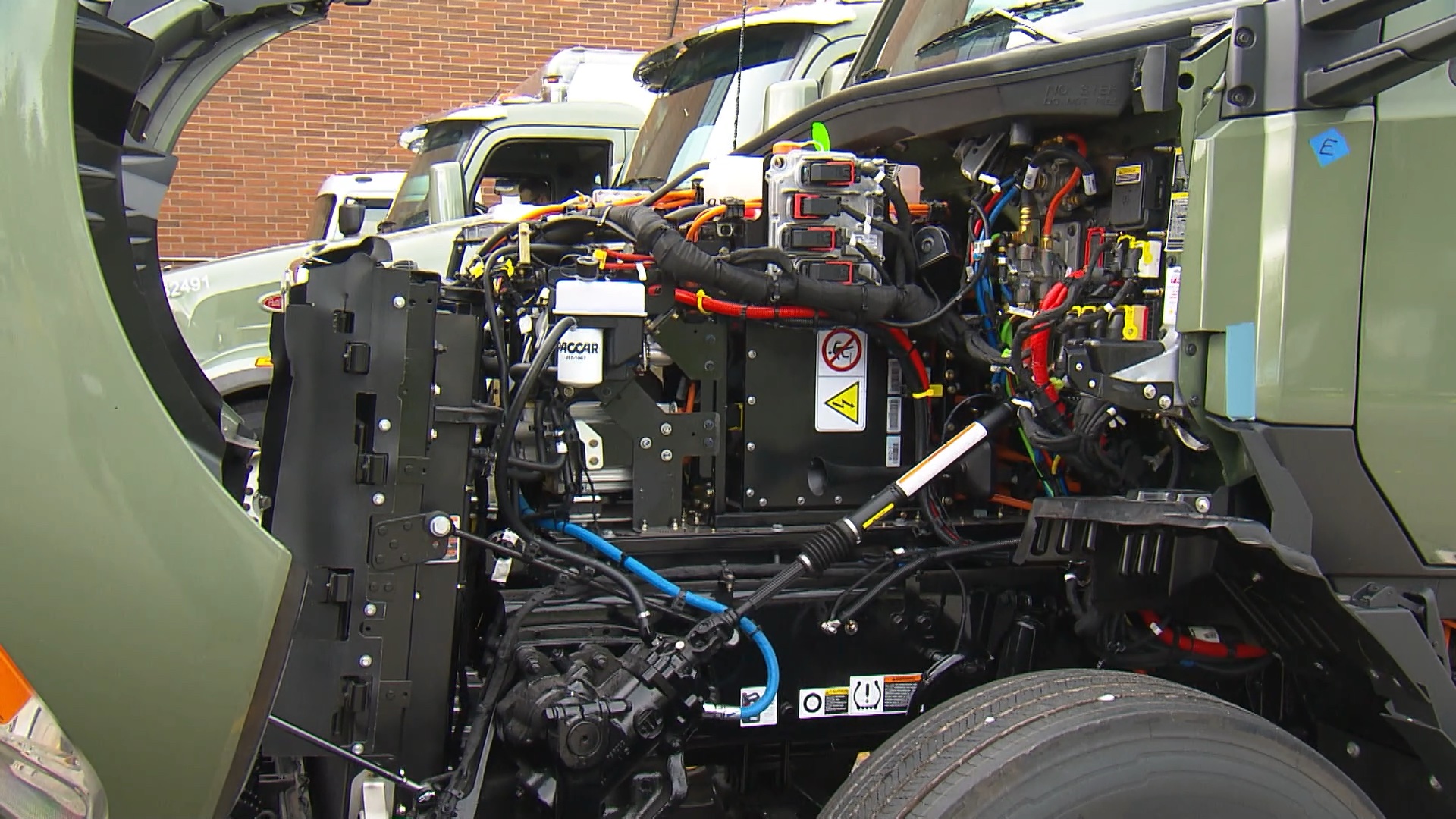

SuperTruck 2, which is now wrapping up, focused on diesel engines, which still, and will, power most trucks for the near future. Several teams were able to incorporate 48-volt mild hybrid systems to enable idle reduction, power the hotel loads, or driver comfort systems, and convert belt-driven accessories, like steering, to electric power, eliminating drag on the engine for more efficient operation. SuperTruck 3 will explore electric and fuel cell power trains over the next few years.

DEREK ROTZ: “As we move forward into research, we’re looking into zero emissions, and the benefits of working with the Department of Energy is not only getting a– a 50/50 cost share to allow us to share the resources on these high risk/high reward technologies, but it also opens us up to the possibility to work with the national lab systems, the university systems, and those folks that have been looking at those cutting edge– edge technologies for years.”

The result has been a super-charged R&D effort that is already paying huge dividends. One SuperTruck 2 team has achieved 16 miles per gallon, 10 more than the current on-road average, and all are on track to surpass the 100% freight efficiency goal, some reaching as much as 170% improvement.

DAREK VILLENEUVE: “We’ve looked at all aspects with an eye towards production. We don’t want to develop things off in a science box that had no means, we really want to look at things that did have a good chance for production.”

Looking at all of these futuristic designs, it’s obvious that lightweighting and aerodynamics play a big part. Technology like rearview cameras and extensive wind tunnel testing has found ways to make the big box less boxy, minimize body gaps, and improve airflow.

KEITH BRANDIS: “When you look at aero, it takes a number of factors that we have to stretch, if you will, and that was the whole purpose, was to see how far we could go with extreme aero, and you’ll see all the skirting along the side of the vehicle, but also to lower the vehicle and use low profile tires, to eliminate the amount of air that builds up around the front air dam.”

Both Peterbilt and Kenworth’s extreme aero designs build around a center seating position to allow a narrow nose. While Navistar’s sleek rig includes a curved trailer roof to maximize clean airflow across the full length. With aerodynamic gains now almost exceeding the realm of what’s possible, looking forward the R&D focus will shift back to the power train, and the target of zero emissions.

DEREK ROTZ: “So… So, decarbonizing commercial vehicles is no easy task. Uh, we’ve been at diesel for over a century now, we’ve kind of perfected it. Going into these zero emissions technologies is a whole new field, so–so it’s learning about new technologies, new technical fields such as electro-chemistry, um, things like that are new to this industry, and those are some of the barriers we need to be able to overcome.”

Here is where collaboration and innovation come into play. All of these manufacturers are up for the challenge and optimistic that zero-emission trucks will be viable not too far down the road.

MAARTEN MEIJER: “Solutions that we see as opportunities are the fuel cell electric vehicles, the hydrogen combustion engine vehicles, and the hybrid powertrains using the more traditional diesel engine concept, but switching to an e-fuel approach.”

So, what’s the bottom line of all this effort? Supertruck-developed technologies can save nearly 6 billion barrels of oil by 2050. To the average truck owner, that could ring up $35,000 a year in fuel savings! And that adds up to environmental and financial savings that benefit all of us in the long haul!